- July 28, 2023

Industrial Protective Gear Detection

Introduction

This presents the implementation of a robust industrial protective gear detection system using the YOLOv8 object detection algorithm and the LabelImg annotation tool. The goal is to improve workplace safety, ensure compliance with safety regulations, and mitigate risks associated with inadequate protective gear in industrial settings.

Problem Statement

Industrial environments pose various hazards to workers, making the proper use of protective gear critical. Traditional methods of manual inspection are time-consuming and prone to errors. This case study explores the application of computer vision techniques to automate the detection of industrial protective gear.

Methodology

Data Collection

A dataset comprising images of workers in different industrial scenarios wearing protective gear is collected.

Annotation with Labeling

The LabelImg tool is to annotate the images by drawing bounding boxes around the protective gear objects and assigning corresponding labels.

YOLOv8 Model Training

The annotated dataset is used to train the YOLOv8 object detection model.

Model Prediction

The trained model is used for prediction by feeding new, unseen images and obtaining bounding box predictions for safety gear objects.

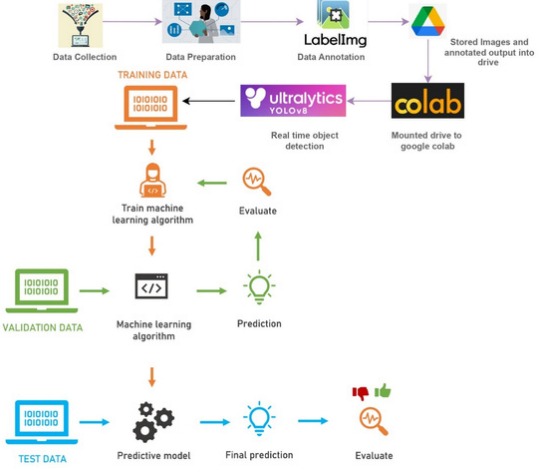

Project Architecture

Benefits

Workplace Safety

Automatically identifies whether workers are wearing required protective gear, helping prevent accidents and injuries.

Compliance Monitoring

Monitoring and enforcing compliance with safety regulations by identifying instances of non-compliance.

Risk Mitigation

By quickly detecting inadequate or missing protective gear, the system allows us to take action and mitigate risks.

Adaptability

Trained models can be fine-tuned to suit specific industrial environments, gear configurations, and additional safety requirements.

Our Approach

- Gathered a diverse dataset of images representing various industrial environments and scenarios where safety gear is required.

- In the data preparation stage, remove grayscale images from the dataset to ensure consistency and compatibility with the YOLOv8 model, which typically requires RGB images and unwanted or irrelevant images from the dataset to maintain data quality and optimize the training process.

- Utilize the LabelImg tool to annotate the safety gear objects within the collected images. This involves drawing bounding boxes around each safety gear item and assigning appropriate class labels.

- Utilize the YOLOv8 model, which is known for its efficiency and accuracy in real-time object detection tasks

- Split the annotated dataset into training, validation, and testing sets, ensuring a balanced distribution of different safety gear objects.

- Train the YOLOv8 model using the annotated training dataset, allowing it to learn the visual features of safety gear.

- The trained model is used for prediction by feeding new, unseen images and obtaining bounding box predictions for safety gear objects.

- After obtaining the final predictions from the predictive model, perform post-processing, visualize results, and take appropriate actions based on the safety gear detections.

- Then it can be utilized in real-time to monitor the industrial environment, generate alerts or notifications when safety gear is not being used and contribute to maintaining a safer work environment.