Industrial Protective Gear Detection

July 28, 2023

YOU MAY ALSO LIKE

Related Posts

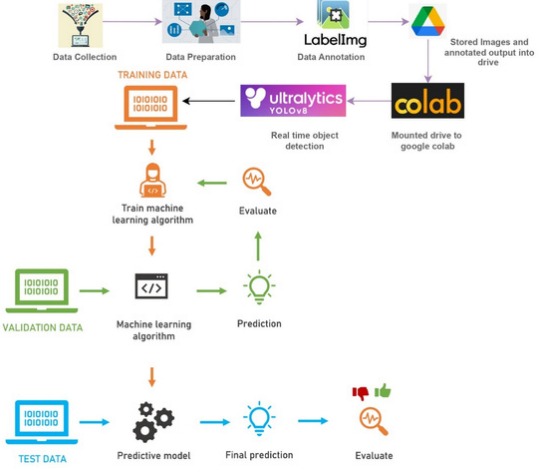

This presents the implementation of a robust industrial protective gear detection system using the YOLOv8 object detection algorithm and the LabelImg annotation tool. The goal is to improve workplace safety, ensure compliance with safety regulations, and mitigate risks associated with inadequate protective gear in industrial settings.

Industrial environments pose various hazards to workers, making the proper use of protective gear critical. Traditional methods of manual inspection are time-consuming and prone to errors. This case study explores the application of computer vision techniques to automate the detection of industrial protective gear.

A dataset comprising images of workers in different industrial scenarios wearing protective gear is collected.

The LabelImg tool is to annotate the images by drawing bounding boxes around the protective gear objects and assigning corresponding labels.

The annotated dataset is used to train the YOLOv8 object detection model.

The trained model is used for prediction by feeding new, unseen images and obtaining bounding box predictions for safety gear objects.

Automatically identifies whether workers are wearing required protective gear, helping prevent accidents and injuries.

Monitoring and enforcing compliance with safety regulations by identifying instances of non-compliance.

By quickly detecting inadequate or missing protective gear, the system allows us to take action and mitigate risks.

Trained models can be fine-tuned to suit specific industrial environments, gear configurations, and additional safety requirements.